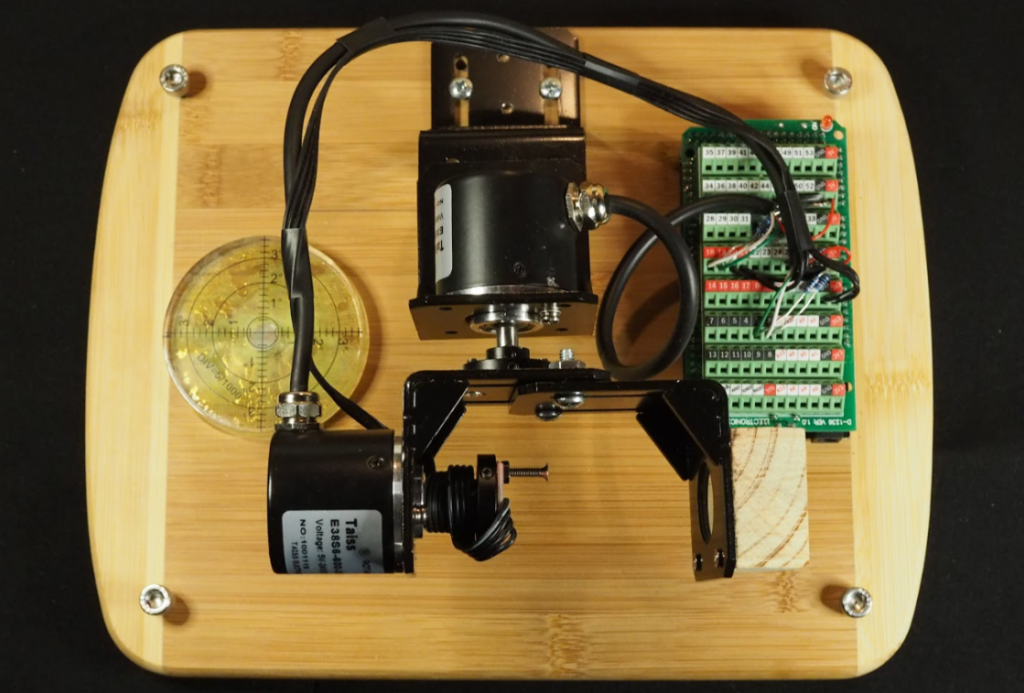

IMU Rate Table

Mobile Bench for Inertial Unit Algorithm Testing and Calibration

Description

The purpose of this project was to make a minimalistic 2-axis test bench for testing and calibration of the Inertial Motion Units (IMU) and verification of developed filtering and calibration techniques. The rate table uses 2 high-precision encoders that generate reference values for the readings of IMU mounted at the center of rotation. This allows for checking the real-time orientation error of (un)filtered IMU and generating data that can be used to feed Neural Networks that improve calibration accuracy by including non-linearity. Below, a description of the investigation on the use of Neural Networks for calibration is presented.

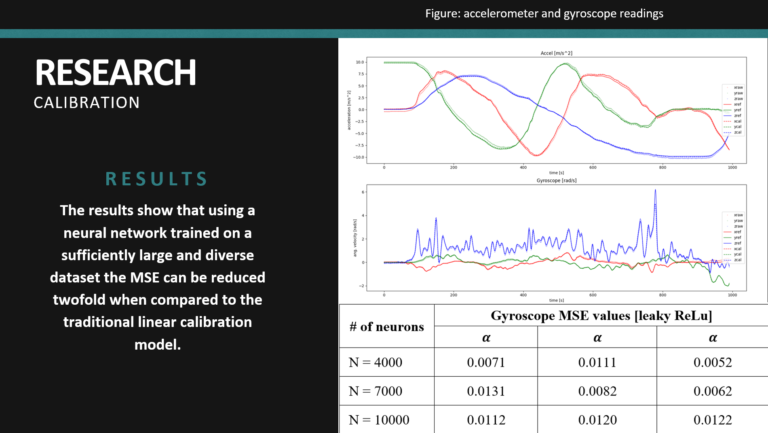

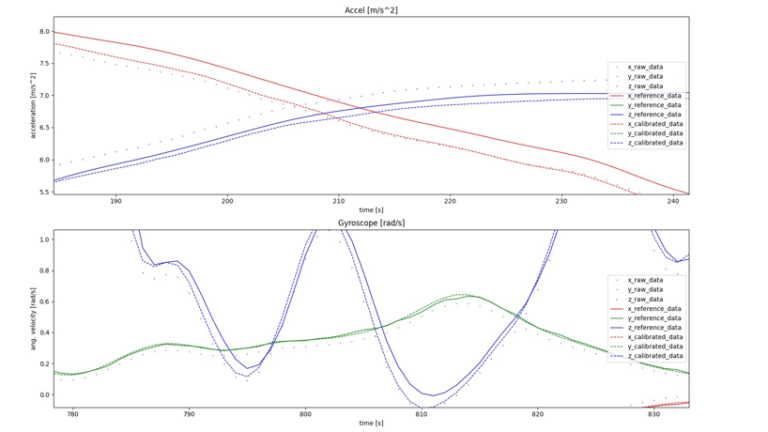

The illustrated method uses measurements from a MEMS IMU with

accelerometer, gyroscope, and thermometer combined with a reference data generated using a rate table to implement an

adaptive calibration technique for both the factory calibration

as well as an online field calibration case. The results show that using a neural network trained on a sufficiently large and diverse dataset the MSE can be reduced twofold when compared to the traditional linear calibration model.

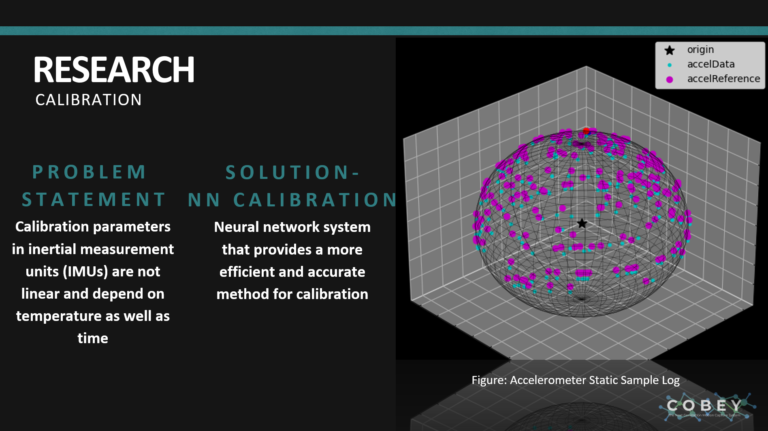

Proper calibration of IMUs is crucial in navigation and mapping in robotics as well as in inertial motion capture applications. The recent developments in the Micro-Electro-Mechanical Systems (MEMS) allow for embedding the functionality of multiple sensors into volume-constrained and low-cost applications. Inertial Measurement Units built using this technology allow for high-frequency sampling of specific force and angular velocity of the sensor body that can be integrated to get position and orientation estimates. Without proper calibration, however, the obtained values quickly accumulate errors due to the integration drift. The problem that the methods described in this paper are attempting to solve is that the true model of the sensor used for calibration in IMUs is not linear, and it depends on the temperature as well as time, rendering traditional calibration techniques insufficient for certain purposes. The solution consists of building a neural network system to provide a more efficient method for calibration to allow for a more accurate initial calibration as well as for an online alignment calibration. This project aims to test the results achieved by Claeson and Marklund in 2019 using real-world data and improve the accuracy of the techniques used. Additionally, the temperature independence assumption was eliminated by including temperature data to train the NNs.

More info: Adaptive IMU Calibration Paper

Skills Used

- Serial Communication (I2C, USB)

- Calibration Routine Design

- System Design

-

Sensor Fusion Algorithms

- Kalman Filtering

- Machine Learning

- PyTorch

- Python

- C++

- LabVIEW

- Quaternion Math

- Scientific Method

- Hardware Design

- Hardware Debugging

- UI Design

Real Time Motion Display + Calibration in LabVIEW

The video above shows a real-time calibrated motion display and the sample log that can be updated during the runtime of the program. It streamlines the process of collecting static accelerator samples that can be used in adaptive calibration later.